INTRODUCTION

Established in 1974, Fluid Controls is an ISO 9001 certified company with certificate no. 00241-2003-AQ-DNV-RvA dated 27.3.2000 from Det Norske Veritas. The company is involved in the manufacture of Double Ferrule Compression Tube Fittings, Valves, Manifolds and specialized accessories for use in instrumentation, hydraulics, pneumatics, and lubrication. The company has a wide range of products for the Oil and Gas Industries, Petrochemicals, Rotating Machinery, Power Generation, Cryogenic and Vacuum Applications among others.

At Fluid Controls, we draw our strength from over twenty-nine years of our experience in the design, engineering, manufacturing and supply of a range of high performance valves and manifolds. These precision products are used for instrumentation in the chemical, petrochemical, and oil and gas industries, as well as for high pressure hydraulics, pneumatics and lubrication.

DESIGN AND MATERIALS

Engineered to specific designs for low, medium and high pressure usage, the valves and manifolds manufactured by Fluid Controls are available in a wide range of materials. These materials are custom-selected for the body, trim and seals to suit the pressures temperatures and fluids used in the pressure lines.

The materials used for manufacturing are based on ASTM/DIN/BS and Indian Standards, depending upon the requirements of our customers. Most of the products manufactured are in carbon steel (ASTM A105) and stainless steel (ASTM A182 F316, ASTM A 479, and ASTM A276 in the SS range). Both the materials conform to NACE MR 01-75 for specified corrosive applications.

Special valves are also available in materials such as high tensile Brass, Nickel, Aluminium, Bronze, Monel, hastealloy C, Titanium, PTFE depending on the specifications of the applications they are required for. Some examples of applications and the materials used are :

- Monel is widely used in oil and gas applications, specifically, for sour gas service where a high concentration of sulphur is found.

- ASTM A182 SS 316 and 316L conforming to NACE MR 01 75 are used where concentrations of sulphur are lower.

- PTFE valves are required for chlor-alkali applications.

For all the valves displayed in the catalogue, the full range of materials for body and trim are available.

The Company also manufactures valves for the naval and sea service that are designed for high pressure pneumatic applications. These valves are available in Nickel, Aluminium, Bronze, SS 316 Ti and SS 321.

The gland seal material for the valves depends on the applications and the temperatures of usage. Standard gland seals are available in PTFE. For high temperature graphitized asbestos and graphoil for temperatures above 1800C and 2700C respectively. For high temperature applications above 1800C and 2700C graphitized asbestos + graphoil are used respectively. Much of the manufacture in Carbon Steel is to ASTM A 105 and in Stainless Steel to ASTM A182, ASTM A 479 and ASTM A 276 respectively.

MANUFACTURE

Fluid Controls products are manufactured using ultra-modern facilities. All designs are first tested and tried in the development section before they go in for general manufacture. The products are also machined for tolerance and compliance with International Standards. For special applications in cryogenic and ultra-high pressure service, the clients first test the products and then place orders for usage.

QUALITY CONTROL

At Fluid Controls, we are committed to ensure that the requirements of our customers are fully met with respect to quality. Consequently, all our products undergo rigorous quality control. We have a full-fledged Quality Control department that is equipped with all required gauges and test equipment. In case of any special tests for which we do not have the facilities, we are backed by the support of nationally recognized laboratories.

For each of our valves, we have developed separate Quality Assurance Programs that are submitted to clients who place large orders. This is a routine feature for all project orders supplied by Fluid Controls, and is a key to the reputation we have acquired over the past twenty-five years.

CERTIFICATION

All valves supplied by Fluid Controls come with ISO 31.b Certificate for material, performance to regular and type tests specified by our customers.

PRODUCT RANGE

Given below are the products manufactured by us at Fluid Controls, which are featured in this catalogue.

A. Needle Valves

We have a comprehensive range of Needle Valves (refer page 1 to 15 ). These valves are available in the following designs : two-way, three-way, multiport, single block and bleed, double block and bleed. These Needle Valves are available with a variety of end connections covering screwed male/female pipe ends which conform to both single ferrule and double ferrule designs.

The Needle Valves manufactured by us have a unique feature : a swivelling, non-rotating plug and thread above the gland seal which ensures that the threads are not left wet by the fluid media. This feature contains the pressure within the envelope below the gland seal to prevent body-leakage, thereby ensuring a long life. The swivelling plug tip also ensures positive aligned seating for repeat operations. The plugs of our SS valves are hardened by a unique process, which prevents indentation of the plug and guarantees long life for each valve that we manufacture.

We are a reputed manufacturer of Needle Valves and have the capability to accommodate the requirements of our customers with any end connections and requirements especially those required for high / medium / low pressure applications as well as for high / medium / low vacuum applications. We also manufacture valves with a variety of seals to suit high to low temperature cryogenic applications.

Given the diversity of our products, the Needle Valves displayed in the catalogue do not cover our entire product range line. Please do not hesitate to contact us for valves of special applications or for those with minor variations. We will be glad to heed to your request.

B. Ball Valves

Fluid Controls Ball Valves were originally designed for use in hydraulic applications. Their applications, however, also extend to instrumentation, pneumatics, hydraulics and other fields. Our Ball Valves are available with a wide variety of end connections (screwed ends, single ferrule ends, double ferrule tube ends) and in a range of two, three and four-way designs.

Fluid Controls Instrumentation Ball Valves for switching service are suitable for panel mounting. They are widely used in two-way as well three and four-way designs with bottom entry and other outlet ports in the same plane. Their compact nature is ideal for applications that require minimum carry-over fluid when switching from one port to the other. These Ball Valves are also used for CNG applications, for static and vehicular installations.

In the field of hydraulics, the Ball Valves we manufacture are available with flanged ends for sizes 1.5″ and above, which conform to SAE and CETOP standards. The Fluid Controls Ball Valves shown in the catalogue (refer pages 34to47) are specifically designed for isolation where the pipes carry SAE and CETOP flange connections with butt weld or socket weld ends.

C. Check Valves

Fluid Controls has a complete range of check valves. The Fluid Controls Non-Return range has a unique sealing arrangement whereby the pressure force is directly transmitted to the body without straining the sealing elements. This sealing arrangement provides for zero leakage over long-life operations. The Non-Return range of Check Valves are robust and suitable for pressures up to 640 bar. They are available with a variety ends screwed, single ferrule tube/male ports, double ferrule tube/male ports single or double ferrule tube ends.

The Compact Non-Return Valve of the CV range is manufactured for high-flow and non-return applications in the hydraulic industry. The leakage in these valves is restricted not to exceed 5 cc’s per second per 1000 to pressure drop. This valve is commonly used where absolute shut-off in the reverse direction is not required and where the frequency of pressure reversal is not very heavy. These valves are generally used in plastic injection moulding machines, die casting machines, and machine tool which use oil hydraulics for their operations.

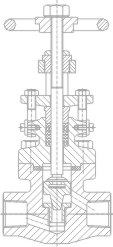

D. Union Bonnet Valves

Where socket weld or butt weld ends are required, screwed bonnet and integral bonnet valves are not ideal. This is because screwed and integral bonnet valves require extensive cooling during socket / butt welding to prevent damage the orifice of the valves. In the past, bolted bonnet OS & Y valves were used whenever socket or butt weld end connections were required.

To circumvent this problem of cooling during the welding operation and provide a low weight compact design, Fluid Controls introduced Union Bonnet Valves as a low-cost solution for bolted bonnet OS & Y type designs which are heavy and require clamping to prevent straining of the piping around the valve. As they are of heavier construction than the Screwed Integral Bonnet Valves, the Union Bonnet Valves allow for centering of the spindle assembly on the body after welding operations. In the welding process, distortion is negligible if normal precautions are taken to cool the body during welding procedure. Union Bonnet Valves with Socket Weld/Butt Weld ends are commonly used as isolation/root valves in instrumentation.

E. OS & Type Bolted Bonnet Valves

luid Controls has a range of Bolted Bonnet OS & Y type valves with a limited range for use in instrumentation applications only. The use of these valves is restricted to isolation and root valves, and limited to butt/weld sockets welds and screwed ends for isolation and root valve service.

F. Pressure Gauge Pin Valves

The power generation industry uses multiple lines in their control rooms which are monitored by pressure gauges. The use of two-valve manifolds for these pressure gauges is impractical, as the gauges require continuous calibration and draining to ease the calibration procedure.

The use of Pressure Gauge Pin Valves manufactured by Fluid Controls can be successfully used for these applications. In its two-way design, these valves are used as simple pressure gauge valves with a draining to atmosphere feature. In its three-way design, they are used for draining and for calibration of the gauge. With the use of these valves the calibration line is connected to the calibration port, the process line is isolated and the gauge calibrated in-situ. The Pressure Gauge Pin Valve is a single valve and not a set of Two Valves (as in a two valve manifold). Medium pressure operations can be serviced with the Integral Bonnet design, while high pressure operations or super-heated steam require the Union Bonnet design.

G. Ultra High Pressure Pneumatic Valves

Ultra High Pressure Pneumatic Valves require a special arrangement for reducing the torque required to operate the valve. To achieve this, the balancing piston feature is widely used. Fluid Controls manufactures a series of Balance Piston isolation Valves with a soft seat arrangement. These valves are widely used in pneumatic applications up to 400 bar and are available in carbon steel, stainless steel, Aluminium and Bronze. They are ideal for quick valve operations as the handle rotates with finger-tip control.

H. Oil Hydraulic Pressure Gauge Isolators

Fluid Controls Pressure Gauge Isolator are of the push-to-read design and are, in effect, miniature special valves. The valves have metal-to-metal spool type sealing ideal for hydraulic applications where the fluid has a certain amount of lubricity. These valves are also excellent for pressure gauges as they are energized when a push button is depressed and de-energized when released. This saves repeated calibration and increases the life of the gauge.

Multi-station pressure gauge isolator valves allow the use of a single gauge for the measurement of upto six lines where a common fluid is used in all the lines measured. These Valves can be used only with fluids which have certain lubricity and not for gas or liquid/gas.