Research & Development

Since 1974, Fluid Controls has focused on designing solutions that meet customer needs and deliver superior product performance. Our ethos established by our founder Dr. Moochhala and carried forward by Dr. Tansen Chaudhari since 2011.

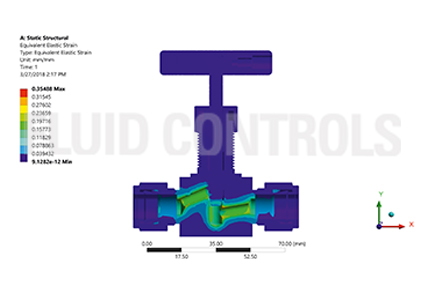

At Fluid Controls, we use the concept of “Design of Six Sigma”, and our innovation and process-focused team constantly challenges our existing product portfolio and provides customized solutions for clients. We use a variety of design tools – from AutoCAD and Solidworks to ANSYS and draw upon our association with local institutions and colleges.

As a validation of our work in research and development, Fluid Controls today is an approved “In-House R&D Centre” by the Department of Scientific & lndustrial Research (DSIR), Government of India.

Product Development Process

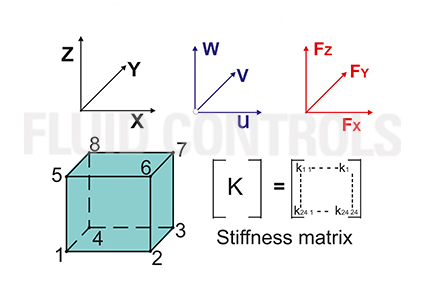

1. Analytical Formulations:

Using the basic laws of physics and hydraulics, we use analytical formulas, wherever applicable, for a basic design formulation. This helps us design the product from First Principles. Our team refers to the latest published papers and standards during the process.

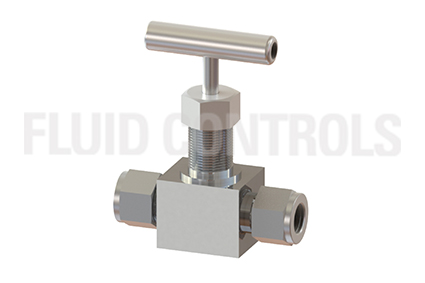

4. Manufacturing:

Once the virtual validation is complete, the models are then validated by our manufacturing experts, after which manufacturing drawings are prepared. Samples are machined on our in-house CNC machines to the highest quality standards.

5. Final Testing:

With our belief that “seeing is believing”, the manufactured product is then taken to our testing center. A range of performance tests are conducted to validate performance parameters. Once the testing is successful, the newly designed product is released.